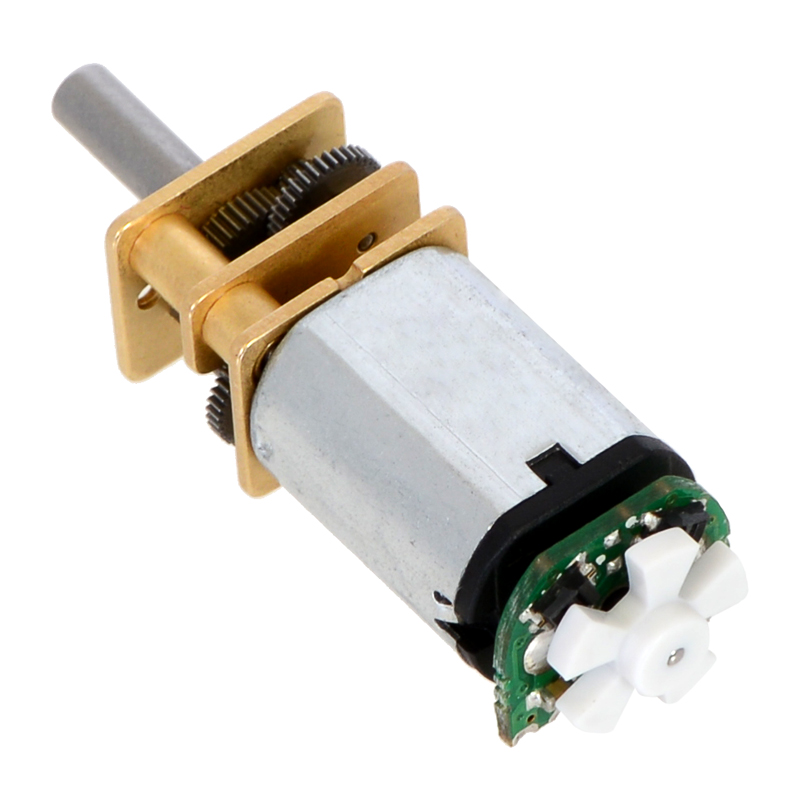

A stepper motor is a machine controlled through a series of electromagnetic coils. The center tube has a series of magnets mounted on it, & the coils surrounding the shaft are alternately given power or not, produce magnetic fields which resist or attract the magnets on the shaft, causing the motor to turn.

An optical encoder is an electromechanical device which has an electrical productivity in digital form relative to the angular position of the input shaft. Optical encoders enable an angular disarticulation to be converted frankly into a digital form.

An optical encoder is a pointed position sensor: It has a shaft mechanically coupled to an input driver which rotates a disc strictly fixed to it. A succession of dense and clear segments is marked on the surface of the disc.

- Advertisement -

Light from infrared emit diodes reaches the infrared receivers through the visible slits of the rotating disc. An analog sign is created.

Then electronically, the sign is amplified and transformed into digital form. This signal is then transmitted to the data processor.

There are 2 types of automatic configurations of optical encoders: rotary encoder and linear encoders. Optical rotary encoders are generally found in motion control systems, while linear encoders are used more especially for linear-positioning applications such as a piston or actuator monitoring method.

- An inner photo detector senses the unbalanced light ray or also called beam & the encoder’s electronics alter the outline into an electrical signal that is then passed on to an external control system through the encoder’s output.

- A linear actuator is a division of motion control systems. Different forms of energy like mechanical, electrical, and hydraulic are used for running these actuators. High current stepper driver Linear motion actuators discover maximum usage in industrial automation and robotics.

- There are different forms of energy that run actuators. These forms of power comprise, hydraulic, pneumatic, mechanical and electrical. Linear actuators are used a lot in robotics and factory mechanization.

- The linear motion actuator is utilized for converting rotating motion into linear motion. There are various types of motors like DC brush, stepper & induction motors that can be utilized as linear actuators. Usage of these motors varies according to the necessity of the application and the load capability of the actuator.

- Today, linear actuators discover wide-spread applications in diverse tasks. It can be used in numerous applications such as solar electronic user items, health, and medical equipment, lawn and garden applications, farming, food preparation devices etc.

- Advertisement -

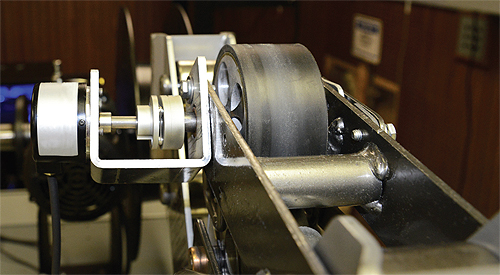

Basically, linear actuators produce motion in a straight (linear) line. This is indifference to the circular motion that is created by the distinctive electric motor. For example, the ejection system in a DVD player needs to make employ of linear actuators.

When it comes to significant motion control applications, the function of linear actuators is indispensable. These machines specifically control the angle, the distance and the repeatability of movement. Right from manufacturing use of commercial applications to home appliances, you will find a linear actuator being used about everywhere. Since they are such a significant component of varied setups, it becomes significant to choose a state-of-the-art manufacturer for your needs.

Whether it is a business actuator, satellite actuator, each of them needs to be at par with international quality standards. A company who has a recognized name as a leader in mechanical motion technology must surely be your ideal choice.

- Simple design

To let the eclectic motor turn the lead screw, usually, the electric motor is connected to a lead screw automatically. A lead screw is recognized to come with a nonstop helical thread which is machined over limits to run along the length. Lead nut or ball nut is generally threaded onto the lead. The rotation of the lead screw is barred with the nut. Thus, the nut drives beside the threads with the turning round of load screw.

The direction of the revolution of the lead screw is the aspect on which the direction of nut is dependent. The faction of the motor can be converted to certain working linear displacement by effortlessly connecting linkages to the nut. You must know that most of the devices are intended either for high force, for high speed or for both compromising on factors.

- Construction

The system with standard motors comes with the motor having a split cylinder which is attached to the similar, side or sticks to the vertical side of an actuator. And motor can also be found build at the backend of the organism. The drive motor that comes with a solid drive stream is geared to the drive screw or nut of the actuator.

Compact linear actuators are assembled with a motor to let the device fits effortlessly in a small space. The inner rotor shaft distance can be effortlessly enlarged to make the drive shaft hollow. And drive screw finds space at the center of the motor & leaves no added gearing between the drive screw and motor.

Comments are closed.